Infrastructure, Technology and Commitment to Excellence

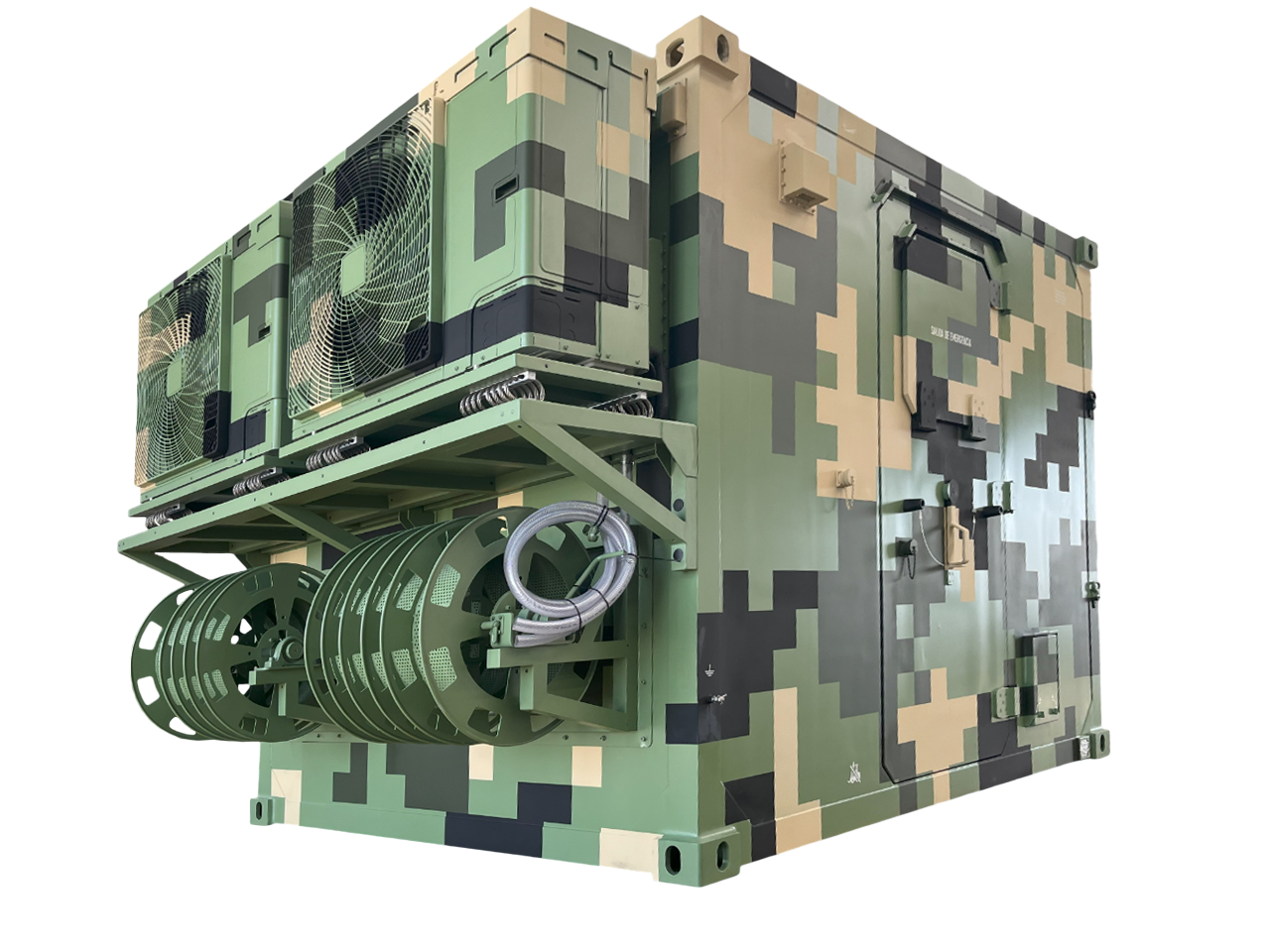

Lecitrailer's Defence Division relies on advanced industrial capabilities, backed by decades of manufacturing experience and state-of-the-art production infrastructure. Our investment in technology, certifications and quality enables us to develop tailor-made solutions for the military sector, ensuring reliability, strength and adaptability in each of our products.

Production

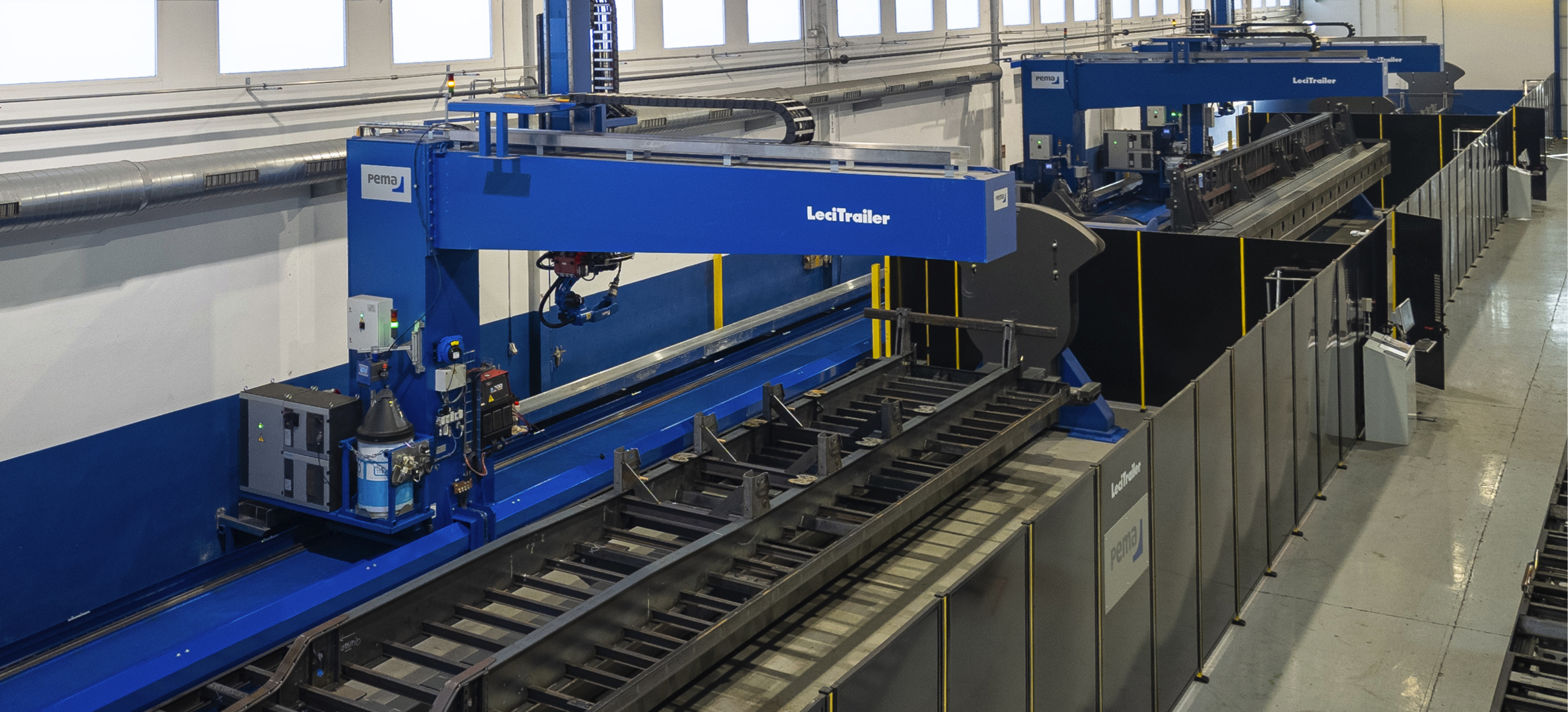

Our production plant, located in Casetas (Zaragoza), is one of the most advanced in Europe in the manufacture of trailers, semi-trailers and sandwich panels.

Flexible manufacturing capabilities, allowing customization of products to military specifications.

Robotized production line, guaranteeing maximum precision and repeatability in each unit.

Specific tests for extreme conditions, validating each product under military operational requirements.

We take advantage of our facilities to offer high-performance military solutions, combining automation and production to order to adapt to the specific requirements of each customer.

Technologies

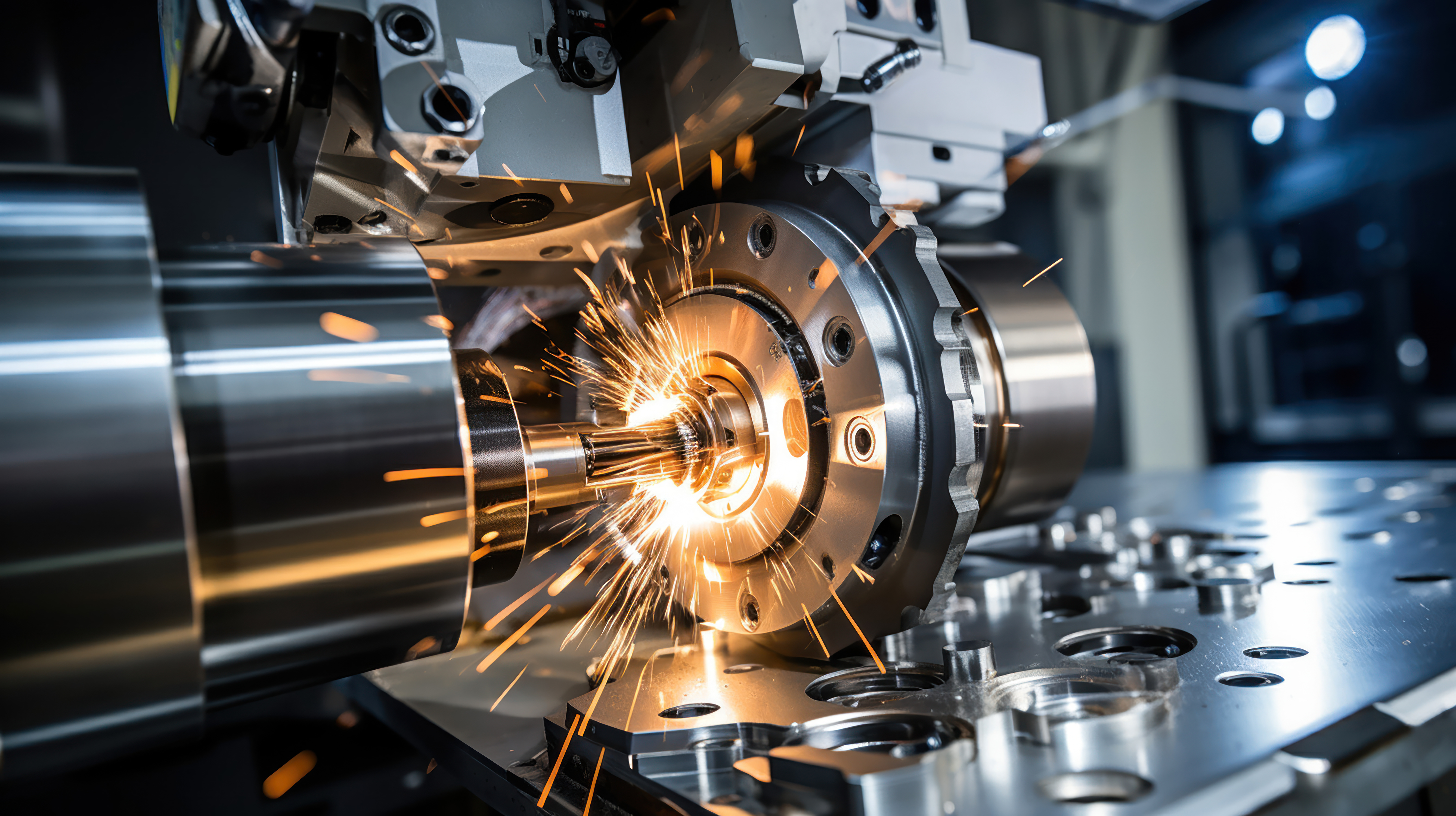

To guarantee maximum quality and durability in our defence products, we apply the following key technologies:

High precision robotized welding, optimizing structural strength and ensuring uniformity in all units.

Sandwich panel manufacturing

Integration / assembly tools

KTL cataphoresis: We have the largest cataphoresis installation in Europe, an anti-corrosion treatment that provides maximum resistance in extreme conditions.

Military grade paint and coatings, complying with the protection standards required in the sector.

Simulation and validation systems to analyze the resistance of materials in demanding environments such as the AC rain tunnel. MIL. STP. 810

Certificates

Our Defence Division complies with the most demanding international standards in the sector, ensuring the quality and safety of each of our products:

ISO 9001 – Quality Management

ISO 14001 – Environmental Management

UNE-EN 15085 – Railway welding certification applicable to the manufacture of military metal structures.

Specific certifications for Shelters and defence structures according to NATO regulations and military standards.

Quality Policy

At Lecitrailer Defence, quality is a fundamental pillar in our product development. Our policy is based on:

Rigorous compliance with national and international regulations in the defence sector.

Quality control at each stage of the production process, with specific tests on each unit manufactured.

Use of high-strength materials and advanced technologies to guarantee maximum durability.

Commitment to continuous improvement, applying innovation in all our manufacturing processes.